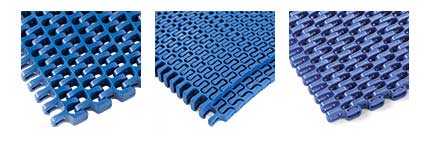

A modular conveyor is a flat belt conveyor where the belt is comprised of many interlocking modules instead of synthetic fabric.

The modular belt is constructed of robust materials which can tolerate low and high temperatures.

What are modular conveyors used for?

Modular conveyors are often used in the food industry due to the ease in which the belt can be removed and cleaned. As the belt consists of multiple interlocking modules it allows for air or liquids to pass through the belt.

Modular conveyors are also used to transport:

- Small items such as screws and components

- Plastic boxes and totes

- Heavier items on pallets

- Cardboard boxes and packages

- Irregular packages, parcels and sachets in soft packaging.

Areas in which modular conveyors can be found include:

- Packaging lines

- Cooling and drying applications (air can permeate through belt)

- Assembly lines

- Tray merging or routing

- Warehousing distribution

- Clean rooms

- Pharmaceutical applications

What are the advantages of using modular conveyors?

- Range of material options

- Can transport sharp items

- No tracking issues

- Easy to clean therefore hygienic

- Suitable for chemicals

- Heat and also cold resistant

- Positive drive

- Permeable belt allows air & liquids to pass through

- Suitable for bends/corners

- Suitable for inclines with flights

- Replaceable belt modules

- Quiet in operation at correct speed

- Doesn’t get misaligned from lateral forces

- Variable speed

What are the disadvantages of using modular plastic conveyor belts?

The cost of the belting itself can be quite expensive due to the labour required to create the interlocked mesh.

These conveyors also cannot run at high speeds unlike a traditional flat belt conveyor. without getting loud. In some environments this could be problematic.

Plastic modular belts also have a set pitch, meaning any belt replacement has to be an exact match to suit the existing sprockets.

Leave a Reply