Belt Conveyor Explained: How It Works and Why It’s Essential in Modern Manufacturing

💡 If you’re looking for a bespoke conveyor system, visit our Belt Conveyors page to explore custom-built solutions designed and built in the UK.

A belt conveyor is a mechanical system designed and built to move materials quickly and efficiently using a continuous belt loop. By doing this, they also lower manual handling, which in turn reduces possible injury to employees and improves welfare. They are most commonly used in warehouses, factories, and production lines. Understanding how belt conveyor systems work can help you choose the best conveyor for your business and improve productivity.

How Do Belt Conveyors Work?

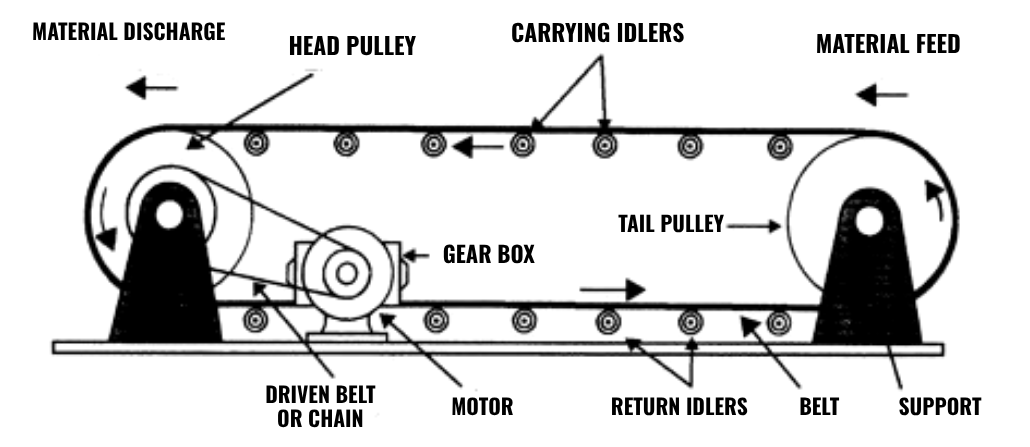

They operate using a closed-loop system. The motor drives the head pulley, moving the belt forward, while the tail pulley maintains tension and stability. Products are placed on the belt and carried to their destination smoothly, with minimal friction or vibration.

A diagram of the general components that make up how a belt conveyor works

A Stainless Steel Belt Conveyor End with PVC Belting

Why Are Belt Conveyors So Widely Used?

Businesses choose conveyor belt systems because they save time, space, and labour. Here are a few key advantages:

-

Efficiency: Automating material transport allows for higher throughput with fewer staff.

-

Space saving: Conveyors can move goods between different levels and around corners, freeing up floor space.

-

Cost-effective: Conveyor belts are typically more affordable than more complex conveyor systems.

-

Versatility: They can handle light parcels, bulk materials, irregular shapes, and delicate products that wouldn’t move well on roller conveyors.

-

Temporary or permanent: For example, builders or landscapers may hire portable conveyor belt to quickly clear sites.

Safety Features of Conveyor Belts

Safety is a critical part of any conveyor installation. Modern belt conveyors can be equipped with:

-

Emergency stop buttons and pull cords along the length of the conveyor.

-

Belt sway switches to stop operation if the belt misaligns.

-

Speed and rip switches to prevent damage to belts, products, and personnel.

-

Belt guards and side guides to contain products and protect operators.

-

Variable frequency drives (VFD) for smooth starts and stops.

The Common Types of Belt Conveyors

-

Modular Conveyors – easy to clean and ideal for hygienic environments.

-

Slat Conveyors – for robust product handling.

-

Portable Conveyors – lightweight and easy to reposition.

-

Swan Neck / Incline Conveyors – for transporting goods between height levels.

-

Trough and Pipe Conveyors – for bulk materials.

-

Sandwich Conveyors – for steep inclines without spillage.

-

Metering Conveyors – for controlled product spacing.

Each type of conveyor can be customized for speed, load capacity, material, and operating environment.

Key Specifications to Consider

Choosing the right belt conveyor specification is essential to achieving long-term performance and reliability. Every detail from the motor type to the belt material influences how efficiently a system runs. That’s why we take a practical, engineering-led approach to ensure each conveyor is designed to meet the specific demands of your process.

Several important factors will determine how well a conveyor will perform under real-world conditions. Our engineers will take the time to completely understand your application before recommending a setup. This is because the right specification can make the difference between a reliable, long-lasting conveyor and one that struggles under load.

- One of the first considerations is the maximum load capacity and belt speed required. These values affect motor sizing, drive selection, and even the choice of belt material. For example, high-speed conveyors moving lightweight parcels demand very different setups to slow, heavy-duty conveyors transporting bulk materials.

- The frame construction is another key factor. We manufacture systems in a range of materials, including powder-coated mild steel, aluminium, and stainless steel, depending on the environment and hygiene requirements. Stainless steel frames are ideal for food or pharmaceutical environments, while mild steel frames are often chosen for general manufacturing or logistics.

- Choosing the right drive configuration — whether that’s a drum motor, shaft-mounted geared motor, or conventional external drive — is equally important. Our team assesses the most efficient solution for your layout, taking into account maintenance access, available space, and the required torque.

- We also look closely at product characteristics, such as size, shape, and weight distribution. Irregular or delicate items might require a specific belt surface or tracking design to ensure smooth transport without damage. In electronics and cleanroom applications, for instance, we often specify anti-static belts to prevent static discharge, while food processing conveyors typically require washdown-rated, blue belting that meets hygiene standards and resists bacterial build-up.

- Finally, environmental conditions — such as temperature, humidity, or exposure to chemicals — play a huge role in material selection and component choice. Our engineers consider every detail to ensure your conveyor maintains consistent performance and complies with relevant safety and hygiene regulations.

By combining these factors, we as a conver manufacturer can continue to deliver fully bespoke conveyor solutions that are efficient, durable, and built precisely for their intended environment.

Conveyor Terminology — Quick Reference

| Term | Meaning |

|---|---|

| Bed | The support structure under the belt |

| Drive Pulley | Powered pulley that moves the belt |

| Idler Pulley | Non-powered pulley |

| Take-Up | Tensioning mechanism |

| Slider Bed | Flat surface supporting the belt |

| Pop-Out Roller | Safety roller that ejects if something gets caught |

| Emergency Stop | Button or pull cord to immediately stop the system |

| Guide Rail | Bars or plates to contain or direct products |

| Lagged Pulley | Pulley with rubber surface for added friction |