-

Belt Conveyors direct from UK Manufacturer

Highly experienced belt conveyor manufacturer

Standard & bespoke conveyors for your specific applications

24 Month warranty as standard*

Expert installation service available

Parts, maintenance & servicing

Proven reliable products with high quality customer service

Belt conveyors manufactured in the UK to your specifications

Phone: 01482 363445 - Email: sales@conveyorsystems.co.uk

SPG Conveyor systems are a UK manufacturer of of proven belt conveyor systems - ideal as stand alone units or for integration into a wider conveyor system. Our wide range of equipment, built using only quality components ensures a reliable conveyor, built to suit your requirements. Please contact our sales team to discuss your requirements.

Phone: 01482 363445 Email: sales@conveyorsystems.co.uk

We manufacture Belt Conveyors to suit your requirements

Each belt conveyor can be delivered fully assembled or installed by our team. Or available for integration into conveyor systems or customer machines. Full white label service is available for resellers. All conveyors are backed by our 24 month warranty*, so you can be assured of a well built, reliable conveyor. Designed and built to suit your specific requirements.

- Standard Belt Conveyors

- True Track Belt Conveyors

- Modular Belt Conveyors

- Slat Belt Conveyors

- Mobile Belt Conveyors

- Mezzanine Belt Conveyors

- Extra Wide Belt Conveyors

- Stainless Steel Belt Conveyors

- Swan neck belt conveyors

- 24 Month Warranty

- Competitive Pricing & Quick Deliveries

- Supplied With CE or UKCA and OEM Manual

- Built Using Quality Components

- UK Manufacturer

- Available fully wired and installed or for integration

- White label service available for resellers

- Installation Service available

- Wide choice of belt types and finishes

Contact Us for a Free quotation

Contact us today to get your conveyor project started

Custom designed conveyor solutions

In-house design team

Helpful customer support team

01482 363445

Home » Belt Conveyors

Belt Conveyors

Belt conveyor systems designed & built to suit your needs and delivered directly from our UK-based factory

Belt conveyors are so versatile that they are used in almost every industrial environment imaginable, so getting the right conveyor for your application can be a challenge. At SPG Conveyor Systems we take the headache out of the specifying and selection process, our helpful sales team and trusted engineers make sure you get the exact belt conveyors you need for the job at hand.

We are a trusted UK-based conveyor belt manufacturer producing not only stand-alone belt conveyors for integration but also complete conveyor systems. Our dedicated team has been helping customers get the exact conveyors they need for the job for well over a decade. From micro belt conveyors to heavy-duty or extra wide belt conveyors, we guarantee that all conveyors are designed and built to the highest standard to suit your exact requirements.

All equipment will arrive fully UKCA or CE marked and complete with operation and maintenance manuals - we aim to make our equipment simple to use, all that you have to worry about is unloading and plugging in.

We have a range of standard conveyors in stock for fast delivery so we can get a belt conveyor to you when you need it most.

Please contact our helpful sales team for a friendly chat about your requirements

Food Production & Packing Conveyors

For sorting, transporting, and packing food items we manufacture fully washable hygienic stainless steel belt conveyors that can be used alongside other processing equipment such as inspection conveyors.

We also manufacture a variety of accumulation equipment including stainless steel rotary tables and plastic modular belt accumulation tables.

Warehouse Packing & Parcel Transport Conveyors

Belt Conveyors are able to transport packets and parcels of varying sizes and weights with irregular shapes whilst a roller conveyor generally can only be used for flat-bottomed items.

We can integrate belt conveyor systems into your existing packing lines or warehouse conveyor systems or design a new fully bespoke conveyor system to suit your requirements.

Belt Conveyors for Manufacturing

We manufacture belt conveyors to fit into your existing assembly or process lines, or we can design completely new conveyor systems as required for your application. Belt conveyors are commonly used for linking machinery as well as for infeed and outfeed systems. Factory conveyor belts are ideal for moving materials and components as well as waste products. For moving large and heavy items, we can manufacture heavy-duty belt conveyors.

Mezzanine Conveyors

Belt conveyors can be used for inclines and declines as well as for transport between floors or mezzanines. Our team have in-depth experience of designing, manufacturing and installing mezzanine conveyor systems and can visit your site to gather the required information, please see the mezzanine conveyors page for more information.

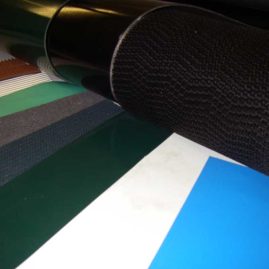

Conveyor Belt Materials for all types of conveyors

Conveyor belting material comes in many varieties with different colours, thicknesses, materials, and features. The most common belt conveyor materials are rubber, silicone, PVC, plastics, and chain belting. Some belt types have added benefits such as being grip-faced, cut-resistant, or having improved tracking. Our team can help you choose the correct belting material and belt width and length to suit your application.

Get a FREE Belt Conveyor Quote today

We are a leading UK manufacturer of Belt Conveyors

Email sales@conveyorsystems.co.uk with your enquiries

Technical Details

Below is a brief overview, for full technical details please contact us

| End Roller Diameter: | From 25mm to 200mm - To suit your loads and application |

| Drive Type: | Geared motor or Drum Motor |

| Drive Position: | Shaft mounted, Underslung or End Drive |

| Belt Type: | 1ply PU, PVC or silicone (industrial or food grade) 2ply PVC (industrial or food grade) 2ply Rubber Other belt options available please contact sales |

| Frame Material: | Mild Steel Stainless Steel |

| Conveyor Finish: | Powder Coated Paint (RAL5010 as standard) Stainless Steel (2B) |

| Conveyor Widths: | 80mm to 2000mm |

| Conveyor Loading: | Please contact sales to discuss your options |

| Support Detail: | Welded 'H' section (+/- 50mm) |

| Optional Extras: |

|

Belt Conveyors FAQ

Get all the answers to your questions about Belt Conveyors as well as advice on how to choose the correct type for your application

What is a Belt Conveyor?

A belt conveyor is a mechanical device used to transport items. They were invented to help transport items on assembly lines.

How does a Belt Conveyor work?

Belt conveyors generally consist of a loop of material that is placed around two or more rollers, with at least one of these rollers, also known as pulleys or drums, being motor powered so it can spin. As the powered roller(s) spins, the friction between the motor and the belt causes the belt to be pulled in the direction that the motor is spinning. The result being the belt continuously rolls over and around the rollers.

How many types of Belt Conveyor are there?

There are many types of belt conveyors each made to suit specific applications, below you can find a list of different types of belt conveyor and their uses.

Standard flat transport conveyor

These are the conveyors you will commonly see at supermarket checkouts, they're the most simple type of belt conveyor and ideal for A to B transport on a flat level surface.

Inclined belt conveyors

Inclined belt conveyors are used for transporting items upwards, either to create a bridge in a conveyor system, to feed materials into machines, or to carry items to and from upper floors or mezzanines. They often use flights or grip face belts to help stop materials from falling back on the conveyor.

Sandwich belt conveyor

Sandwich belt conveyors consist of two belt conveyors running parallel and face-to-face so the items to be transported are 'sandwiched', between them and held in place by gentle pressure. Confusingly, sandwich conveyors are also a type of conveyor that is made specifically to help people make sandwiches.

Trough conveyor

Trough belt conveyors have flexible belts that are folded into a trough U shape using a series of rollers on the bottom and sides to prevent spillages. They are used for transporting fine or lightweight materials, aggregates, soil, and rubble.

Pipe conveyor

Similar to trough conveyors, they also have rollers around the undersides of the belt to shape the belt, though this time the belt is folded around into a closed circle O shape to create a pipe, again these are used for loose materials.

Modular belt conveyor

Modular belt conveyors have a belt consisting of rigid plastic interlocking modules that make the belt much stronger whilst still allowing the belt to curve and flex. They are also positively driven by sprockets which means they do not slip.

Slat conveyor

Slat conveyor belts are similar to modular belts however the slats are linked in a single chain and do not have the same side flexing capabilities as modular belts. They are ideal for transporting cans, bottles, and aerosol canisters.

Belt Conveyor Gallery

All the conveyors shown below were manufactured for our customers in our UK based factory.

Our Clients

Working With Us

SPG Conveyors are used daily by a wide range of third-party logistics, manufacturing, food production, and product assembly businesses in the UK.

We offer tailored solutions to suit our customers' needs:

- Warehousing & Logistics Transport Conveyors

- Factory & Production Line Conveyor Belts

- Packing Lines

- Food & Drink Conveyor Belts

- Conveyors built for integration within other equipment

- Subcontract conveyor manufacturing

- Happy to work with resellers and OEMs

If you need modular conveyors for your business then please contact us by phone, email, or try out the live chat feature for a free no-obligation quotation.

Call:01482 363445

Email: sales@conveyorsystems.co.uk

Supporting our customers & their products

SUPPORT

Our excellent customer service team are available for ongoing customer support

DELIVERY

Conveyors delivered fully wired ready for work or installed by our team across the UK

WARRANTY

All products come with two year warranty & supplied UKCA / CE marked with associated manuals.

SERVICE

All products come with service packages to ensure optimal performance and ongoing reliability.