Roller Conveyor Explained: How It Works and Why It’s Essential for Various Applications

💡 If you’re looking for a bespoke conveyor system, visit our Roller Conveyors Page to explore custom-built solutions designed and built in the UK.

What Is a Roller Conveyor?

A roller conveyor is a type of material-handling equipment designed and built to use a series of rollers mounted on a frame to transport goods from one point to another. An important piece of equipment for any warehouse, manufacturing plant, packaging line, or distribution centre. These conveyors are favoured for their efficiency and reliability in moving a wide variety of items — from light cartons and parcels to heavy pallets and crates.

How do Roller Conveyors Work

The basic principle behind roller conveyors is simple: items placed on the rollers move in the direction the rollers spin. Rollers can be powered by gravity, manual push, or electric drives. Without the rollers spinning, the conveyor functions like an ordinary table.

Roller conveyors come in two main types:

-

Gravity Conveyors: These systems rely on the force of gravity (or a gentle manual push) to move items along the rollers. Because there is no motor driving the movement, these are cost-effective and relatively simple to install and maintain. They’re ideal for straightforward transfers of medium to light loads in a flat or gently sloped layout. Sometimes these conveyors are used to manually push items along.

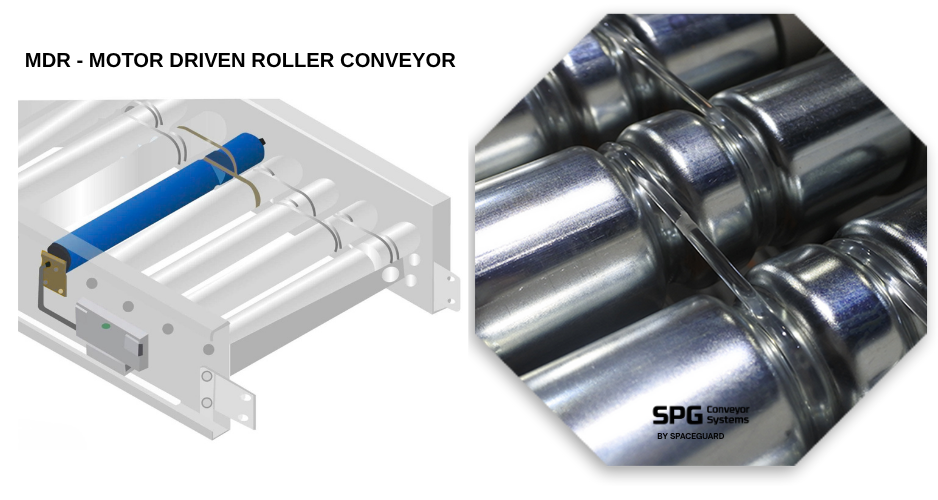

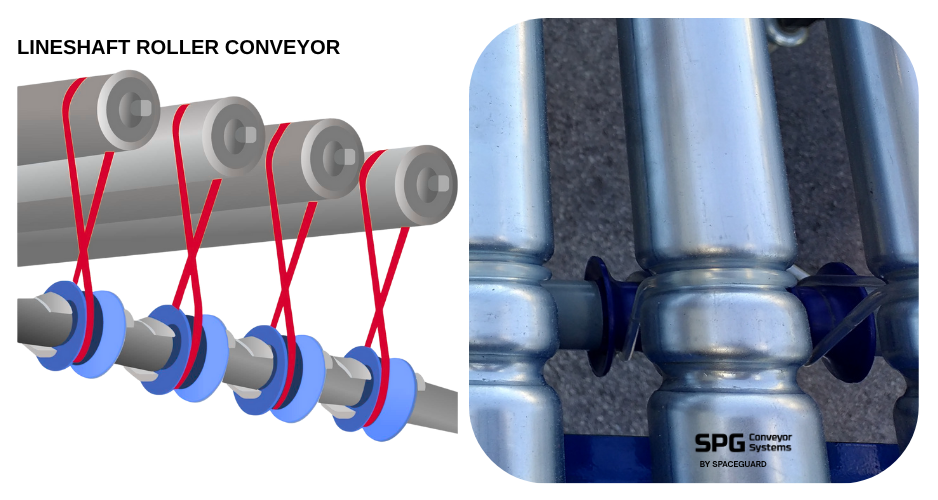

- Driven Conveyors / Electric Drives: In these systems, one or more rollers are powered (via motorized shafts, belts, or chains) to provide controlled, consistent movement. This makes them suitable for heavier loads, automated systems, varying speeds, accumulation zones, or integration with sorting/packing lines. The diagrams below show two example diagrams of motor-driven conveyors and lineshaft conveyors.

By selecting between gravity and driven roller conveyor systems, you can match the equipment to your specific workflow, load type, and throughput requirement.

Why are Roller Conveyors so commonly used?

Here are some of the key benefits and reasons these conveyors are widely used:

-

Versatility: They handle different product types — cartons, crates, trays, pallets — and adapt easily into production lines, packing areas and logistics zones.

-

Durability: With minimal moving parts (especially in gravity systems), the conveyors tend to be robust, low-maintenance and reliable over time.

-

Efficiency in material flow: By automating part of the transport process inside your workspace, they reduce manual handling, cut down on labour costs and improve safety.

-

Customisation potential: Whether you require a standard roll-through system or a bespoke configuration (e.g., multi-zone driven rollers, accumulation, incline/decline sections, specialist frames or drives), these conveyors can be engineered to suit your process.

-

Space optimisation: With modular framing and flexible layouts, these conveyors integrate well into many environments — helping you streamline product movement without massive floor-space expansions.

Key Conveyor Safety Features

Key safety elements that help ensure smooth and secure operation include:

-

Roller guards and protective covers – prevent accidental contact with moving rollers and pinch points.

-

Emergency stop buttons – allow operators to quickly stop the conveyor in case of an obstruction or hazard.

-

Safety sensors and automatic shut-off systems – detect jams or blockages in driven conveyors, reducing the risk of equipment damage.

-

End stops and side guides – keep products stable on the conveyor and prevent items from falling or rolling off.

-

Anti-pinch roller spacing – designed to protect hands and fingers during operation or maintenance.

-

Clear safety signage and visual indicators – mark loading zones and restricted areas for safer workflow management.

-

Stable frame construction and non-slip feet – ensure the conveyor system remains secure, even under heavy loads.

-

Regular safety inspections and maintenance checks – help identify wear or misalignment early to maintain reliable, safe performance.

Most Common Types

-

Gravity Conveyors – A simple, cost-effective system that uses gravity or manual push to move items along the rollers. Ideal for light to medium loads, order-picking lines, and packaging areas where powered movement isn’t required.

-

Driven Conveyors - These conveyors use motors, belts, or chains to drive the rollers and provide consistent, controlled movement. Suitable for heavier products, high-speed transfer, or integration with automated production systems.

-

Motorised Conveyors (MDR) – Equipped with individual motorised rollers, these systems offer precise control, energy efficiency, and low noise levels — perfect for smart manufacturing or automated distribution lines.

-

Chain-Driven Conveyors – Designed for heavy-duty handling, these conveyors use chain drives to synchronise rollers and transport large pallets, drums, or steel components safely and efficiently.

-

Line Shaft Conveyors – Use a rotating shaft and drive bands to power multiple rollers simultaneously. Commonly used in packaging and light assembly applications for smooth, low-maintenance operation.

-

Accumulation Conveyors – Allow items to collect or queue without contact, using sensors or controls to maintain spacing — ideal for buffering zones in automated systems.

Conveyor Terminology – Quick Reference

| Term | Definition |

|---|---|

| Roller Conveyor | A conveyor system that uses a series of rollers to transport goods, available in gravity or driven configurations. |

| Gravity Conveyor | A non-powered conveyor that relies on gravity or manual push to move items along the rollers. |

| Driven Conveyor | A powered conveyor where rollers are motorised or chain-driven for consistent movement. |

| Motorised Drive Roller (MDR) | A type of driven roller with built-in motors inside the rollers, allowing precise, quiet, and energy-efficient operation. |

| Chain-Driven Conveyor | A heavy-duty conveyor where rollers are powered by a continuous chain, ideal for large or heavy loads. |

| Line Shaft Conveyor | Uses a rotating shaft connected by drive bands to power multiple rollers simultaneously, often used for light-duty operations. |

| Accumulation Conveyor | Designed to let items queue or stop temporarily without pressure or damage, useful in packaging or sorting lines. |

| Conveyor Frame | The supporting structure that holds and aligns the rollers or belt components. |

| Roller Pitch | The distance between the centres of two adjacent rollers — affects how smoothly products move along the conveyor. |

| End Stop | A barrier at the end of a conveyor that prevents items from rolling off the line. |

| Side Guide | Rails fitted along the conveyor edges to keep products aligned and prevent lateral movement. |

| Conveyor Bed | The main section of the conveyor that supports the rollers and carries the load. |

| Drive Pulley / Drive Roller | The component that provides motion to the conveyor rollers or belt via motor or chain drive. |

| Return Roller | Rollers positioned underneath to support the return section of a belt or chain. |

| Transfer Point | The area where products move from one conveyor or system to another. |

| Conveyor Guarding | Safety enclosures or shields that protect operators from moving parts and pinch points. |

| Tapered Rollers | Rollers with a slightly conical shape, used for curved conveyor sections to maintain product orientation. |

| Modular Conveyor | A conveyor made up of interchangeable sections, allowing easy expansion or reconfiguration. |

| Conveyor Zone | A segment within a driven conveyor system that can be controlled independently for sorting or accumulation. |

Leave a Reply