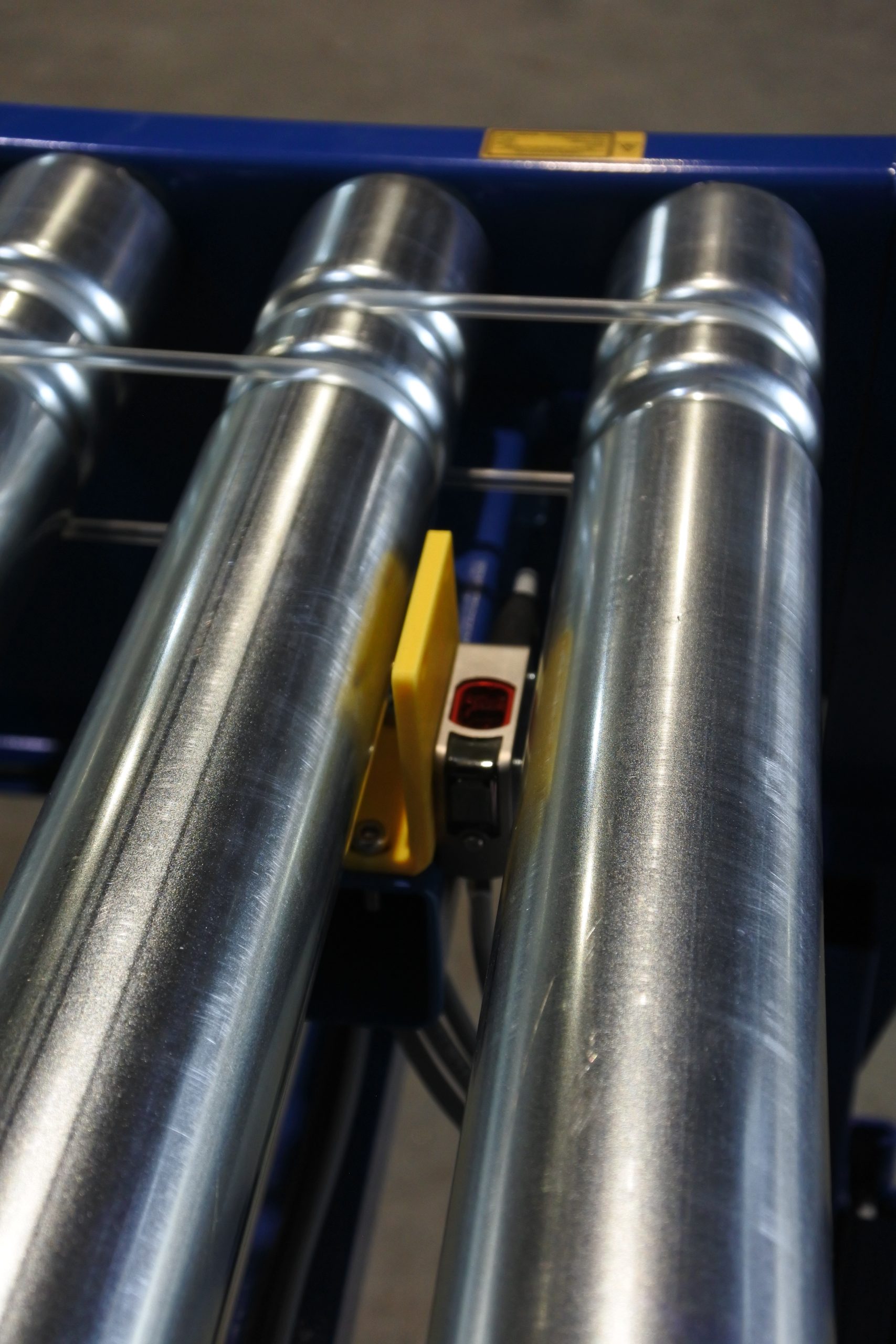

In most material-handling systems, PEC sensors play a very important role in keeping products flowing safely, efficiently, and without operator intervention. We design and build driven roller conveyors for every industry—from e-commerce fulfilment to manufacturing. Photoelectric cell sensors are a commonly requested component in many of the automated or semi-automated conveyor lines that we build.

Below, we answer the key questions customers often ask us, explain the different types of photoelectric sensors used on conveyors, and dive deeper into two types used on our recent bespoke powered roller conveyor projects: diffuse and retro-reflective sensors.

Learn more about powered roller conveyors with zoned PEC sensors in our video below

What Does PEC Mean?

PEC stands for Photo Electric Cell.

A PEC sensor uses a beam of light (usually infrared or visible red) to detect the presence or absence of an object without physical contact.

On a roller conveyor, the PEC sensor is typically used to detect when a product reaches a specific point, when a zone should stop, or when the rollers should restart.

What Is a PEC Sensor?

A PEC sensor works by using light emission and detection. When a product blocks or reflects the beam, the sensor activates.

These sensors are best used for zero-pressure accumulation, flow control, safety, and automated spacing on conveyor lines.

How Does a PEC Sensor Help Users of Roller Conveyors?

PEC sensors play a vital role in achieving accurate product detection, confirming exactly when a box, tote, parcel, or product enters a conveyor zone. On a driven roller conveyor, they enable automatic start and stop control, allowing the rollers to run only when necessary and pause when a product is present. This intelligent zone control helps prevent product collisions, ensuring that items do not run into each other—an especially important feature when handling fragile goods.

They also contribute to improved operator safety by reducing unnecessary manual handling and helping workers maintain safe operating distances. Overall efficiency and throughput are significantly enhanced, creating a smoother, faster, and more reliable flow of goods across the system.

From our experience designing conveyor systems tailored to precise customer requirements, we’ve found that PEC sensors are one of the simplest yet most effective ways to boost productivity and minimise unnecessary downtime.

Types of PEC Sensors Used in Conveyor Systems

There are three main categories of PEC sensors used in roller conveyor systems

Diffuse PEC Sensor

Retro-Reflective PEC Sensor

Through-Beam PEC Sensor

The best choice depends on the conveyor layout, product type, environment, and required detection accuracy.

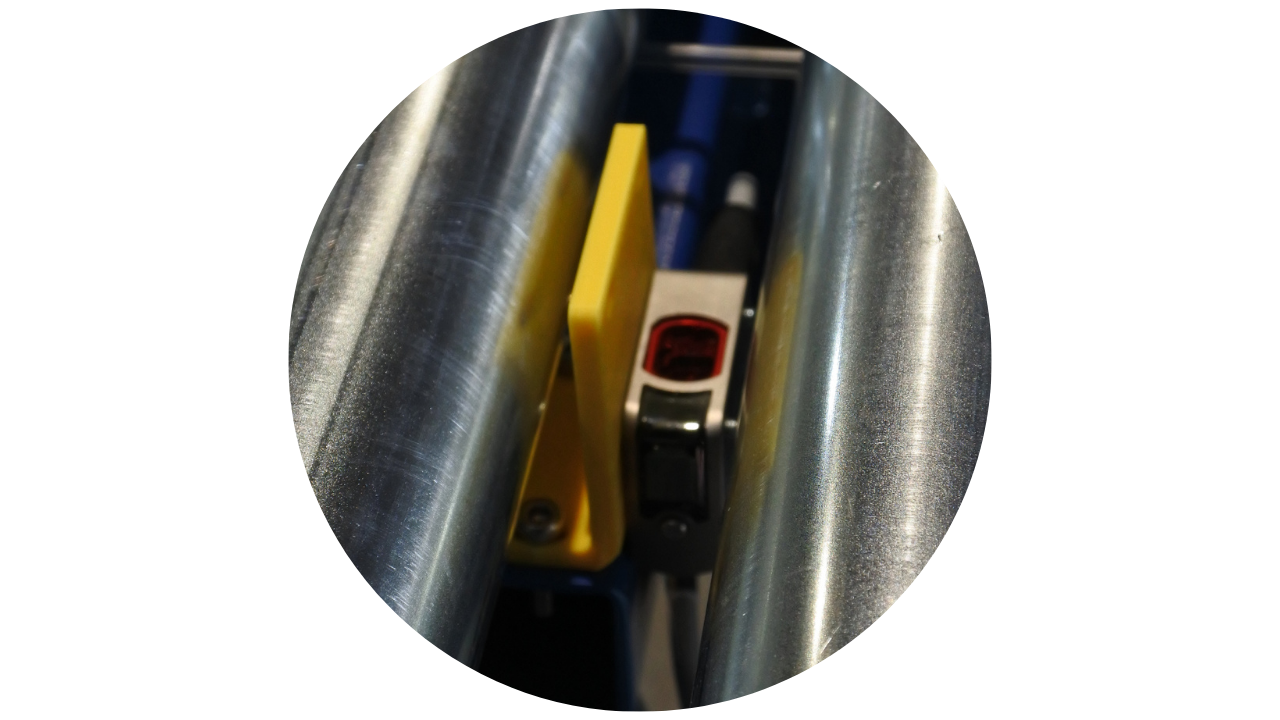

Diffuse PEC Sensor (Diffuse Photoelectric Sensor)

A Diffuse PEC Sensor (Diffuse Photoelectric Sensor) works by emitting a beam of light directly toward the product on the conveyor. When the light hits the object, it reflects into the sensor, confirming that the item is present. The process is simple: the sensor sends out light, the light strikes the object, and the returning reflection allows the sensor to register detection.

One of the main advantages of diffuse PEC sensors is that they do not require a reflector, making installation easy on the sides of a conveyor. They are excellent for detecting parcels, boxes, totes, and general goods, especially within short-range applications. However, like any sensor type, they have some limitations. Reflective or shiny surfaces can occasionally interfere with accurate detection, and their sensing range is typically shorter than retro-reflective or through-beam alternatives.

We commonly use diffuse PEC sensors on driven roller conveyors where product presence needs to be monitored, on packing lines where operators manually remove items, and in shorter conveyor zones. They perform particularly well in light to medium industrial environments. Overall, diffuse sensors offer reliable detection and remain a cost-effective solution for the majority of standard conveyor systems.

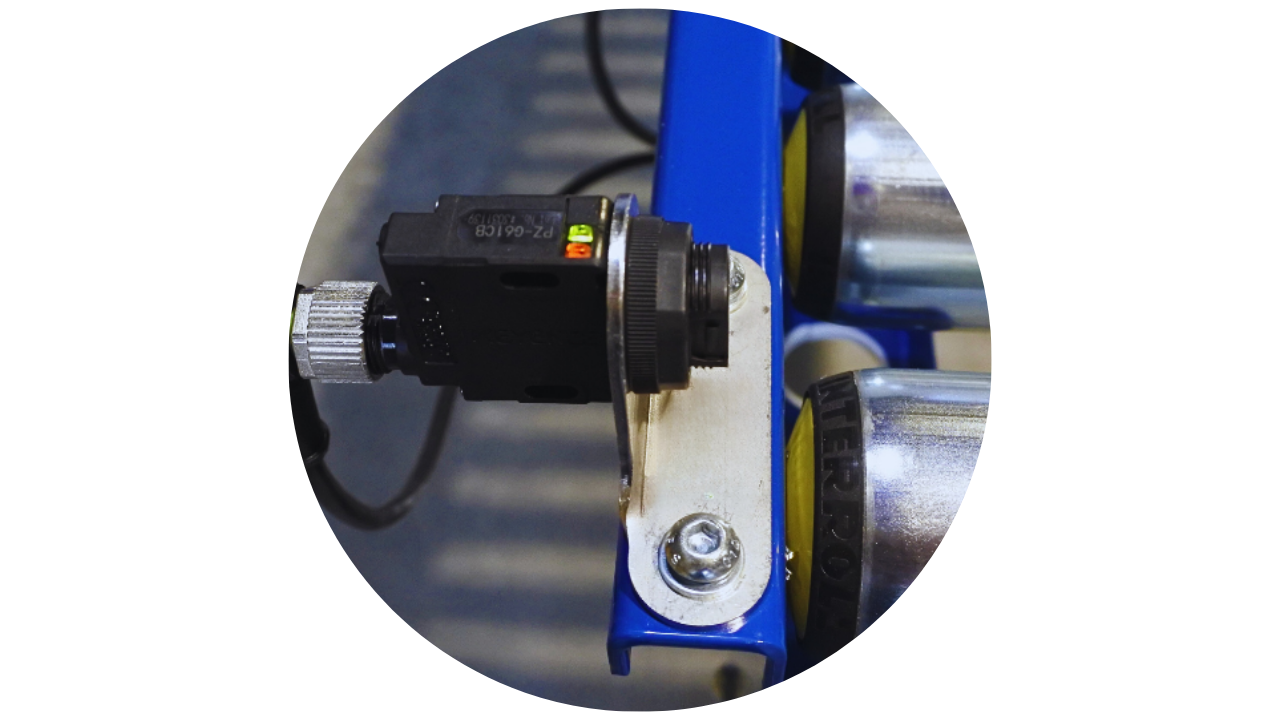

Retro-Reflective PEC Sensors

A Retro-Reflective PEC Sensor (Reflector Type) operates by sending a beam of light toward a reflector positioned opposite the sensor. The beam returns consistently to the sensor, creating a stable signal. When a product passes between the sensor and the reflector, the beam is interrupted, and the sensor registers the detection.

The way it works is straightforward: the sensor emits a light beam, the reflector bounces that beam back, and the sensor continuously receives it until something blocks the path. As soon as the beam is broken, the system identifies that a product is present.

Retro-reflective PEC sensors offer several advantages. They provide a longer detection range, perform reliably in dusty or outdoor environments, and work well with dark or low-reflection surfaces that diffuse sensors might struggle with. They are also easy to align, requiring only a reflector rather than wiring on both sides of the conveyor. However, there are a few limitations to consider. Products can sometimes unintentionally reflect the light if they have highly reflective surfaces, and the reflector must be kept clean to maintain accuracy.

We typically use retro-reflective sensors on longer roller conveyor zones, high-speed driven roller conveyors, and in packaging, logistics, and warehouse operations. They are also ideal in areas where dust or debris might disrupt diffuse sensors and for detecting irregularly shaped goods. In our experience, retro-reflective PEC sensors are among the most dependable and versatile options for industrial conveyor systems.

What Conveyors Can PEC Sensors Be Used With?

PEC sensors can be installed on almost any conveyor type, such as:

Powered roller conveyors

Most commonly used for zone control, accumulation, and safe spacing.

Gravity roller conveyors

Used for presence detection at transfers or pick stations.

Modular belt conveyors

Perfect for indexing, counting, and product flow management.

PVC belt conveyors

Help with alignment and automated process control.

Multi-level or tiered conveyor systems

Useful for vertical flow control where multiple conveyors operate independently.

We design conveyors with sensor mounting built in, ensuring accurate alignment and high reliability.

Which Industries Use PEC Sensors the Most?

PEC sensors are widely used across:

-

E-commerce fulfilment

-

Third-party logistics (3PL)

-

Distribution centres

-

Manufacturing

-

Food & beverage processing

-

Automotive assembly

-

Packaging operations

-

Postal & parcel sorting

Any industry that uses roller conveyors, driven roller conveyors, or automated handling systems relies heavily on PEC sensor technology.

How PEC Sensors Improve Workplace Processes

From real-world installations, the benefits include:

1. Zero-pressure accumulation

Products no longer collide, preventing damage and reducing returns.

2. Better product spacing & line control

Crucial for scanners, packing, weighing, labelling, or quality checks.

3. Improved operator efficiency

Workers can remove or add products without disrupting flow.

4. Lower energy consumption

Driven roller conveyors only run when a zone is occupied.

5. Enhanced safety

No need for manual stop-start buttons—automation handles it.

6. Increased throughput

Fewer stoppages and smoother flow means faster processing.

Our Experience Building Conveyor Systems with PEC Sensors

As a UK-based manufacturer, we design and build custom-driven roller conveyors, complete with PEC sensors, zone control, wiring, and PLC integration.

-

Product accumulation

-

Pack line control

-

Sortation

-

Simple infeed/outfeed detection

-

Multi-level conveyor automation

—we can design a conveyor system that fits your product, speed, and workflow.

Get in touch today with your enquiries and receive a free quote

sales@conveyorsystems.co.uk 01482 363445