-

SPG Conveyor Systems a Leading UK Modular Belt Conveyor Manufacturer

Highly experienced conveyor manufacturer

Standard & bespoke modular conveyors for your specific applications

24 Month warranty as standard*

Expert installation and maintenance services available

Quick deliveries often available

Proven reliable products with high quality customer service

Home » Modular Belt Conveyors

High-Quality Modular Belt Conveyors from a Trusted UK Manufacturer

Reliable modular belt conveyors designed and built in the UK.

SPG Conveyor Systems is a professional UK manufacturer with over 30 years of experience in designing and producing high-quality modular belt conveyors and modular conveyor systems for a wide range of industries. We manufacture standalone modular conveyors for integration into an existing line, but we can also manufacture a complete turnkey conveyor system. Our modular belt conveyors provide a durable, efficient, and hygienic solution for safely and reliably transporting goods.

All equipment is fully UKCA or CE marked, ensuring compliance with current safety and quality standards.

Please contact our helpful sales team with your enquiries.

Our modular belt conveyors are extremely robust, making them suitable for most transport applications. Their hard-wearing modular belting—available in a range of material options—can even handle sharp-edged products without compromising performance. The easy-to-clean open design construction makes modular conveyors the ideal choice for direct food-contact environments, washdown areas, and facilities where chemicals are often used.

Thanks to their positive-drive mechanism, modular belt conveyors deliver increased reliability and consistent performance, even in demanding conditions. We also manufacture conveyors using traditional flat-belt materials for applications where they are more suitable.

What is a Modular Belt Conveyor?

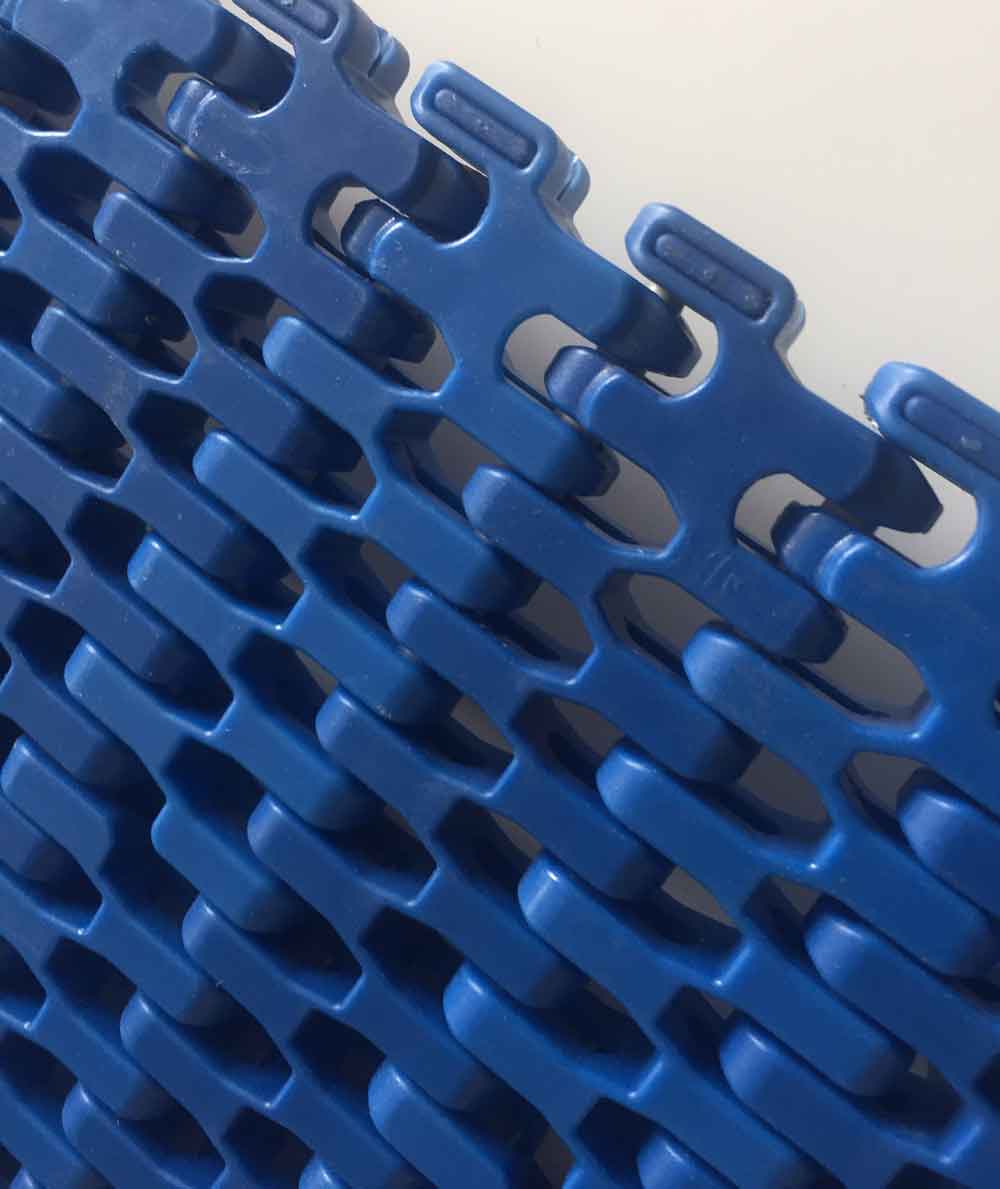

A modular belt conveyor is a type of material handling equipment that uses interlocking plastic modules—rather than a traditional continuous belt—to transport products from one point to another. These plastic modules form a durable, versatile, and easy-to-maintain conveying surface, making modular conveyors ideal for a wide range of applications. They are commonly used in food processing, manufacturing, packaging, engineering, and environments where hygiene, robustness, or reliability is essential.

Modular belt conveyors are extremely robust and well-suited for most transport applications. Their hard-wearing modular belting, available in multiple material options, can withstand sharp-edged products without compromising performance. The open, easy-to-clean design makes them particularly effective in direct food-contact areas, washdown environments, and facilities where chemicals are used.

Thanks to their positive-drive mechanism, modular belt conveyors offer exceptional reliability, reduced belt slippage, and consistent performance—even in demanding or wet conditions. For applications where a modular belt may not be the best fit, we also manufacture conveyor systems using traditional flat-belt materials.

Modular Belt Conveyors

Technical Details

All modular belt conveyors are delivered fully wired and complete with manuals and food-safe materials information. Alternatively, you can request installation from our experienced installation engineers. Click here to learn more about how modular belt conveyors work.

Conveyor Details

| Min/Max Length: | 500mm - 10,000mm |

| Min/Max Width | 150 - 2000mm |

| Min/Max Height: | 130 - 1500mm |

| Frame material: | Mild Steel (Powder coat paint finish) Stainless Steel |

| Supports: | Welded ‘H’ section - with levelling feet or castors |

| Drive Type: | Geared motor (end-drive) |

| End Diameter: | 100mm |

| Load Rating: | Up to 100kg per meter |

Belt Details

| Materials: | Polypropylene (PP) Polyethylene (PE) Acetal, Polyacetal (POM) |

| Belt Types: | 1/2”, 1" , 2" pitch Open or closed pitch Side flexing |

Plastic modular belting has a range of benefits including:

- Extremely robust and resistant to wear

- Can be used to transport sharp edged items

- Modular plastic belting is easy to install, repair, replace, and clean

- Suitable for use in hot & cold environments (-50°C to 90°C)

- Resistant to chemicals

- Food safe

- Positively driven using sprockets so the belt does not slip

- Suitable for use in wet environments

- Modular belts do not need to be tracked

- Highly versatile, used for straights, bends, inclines, and declines

- Sidewalls and flighted belts available

- Available in many materials, colours, and finishes

Get a FREE Modular Belt Conveyor Quote today

We are the leading UK manufacturer of Modular Belt Conveyors

Email sales@conveyorsystems.co.uk with your enquiries

Application Example - Packing Conveyor

In this example, you can see the conveyor is used for transporting packaged food (cucumbers) so they can be packed into crates.

This conveyor system includes a belt conveyor to transport items through the hole in the wall and a twin-lane modular belt conveyor with side guides.

Modular belt conveyors can be used for both packaged and unpackaged food products as they are suitable for washdown and use in wet environments.

Application Example - Box Turning Conveyor

In this example, you can see the conveyor is used for turning boxes to the correct orientation ready for labelling.

This conveyor system features two modular conveyors with side guides set at right angles, an enclosed box pusher, and a turning wheel to gently turn the boxes prior to them reaching the outfeed.

These types of conveyors can save hundreds of hours of labour, increase overall efficiency in packing lines, and help improve the uniformity of labelling.

Modular Conveyor with Packing Benches

This video demonstrates one of our bespoke conveyors in use with packing benches. We can provide modular conveyors as a singular unit or with the intent to be integrated into your process and existing equipment and robotics.

Modular Conveyor Gallery

All the conveyors shown below were manufactured for our customers in our UK based factory.

Our Clients

Working With Us

SPG Conveyors are used daily by a wide range of third-party logistics, manufacturing, food production, and product assembly businesses in the UK.

We offer tailored solutions to suit our customers' needs:

- Warehousing & Logistics Transport Conveyors

- Factory & Production Line Conveyor Belts

- Packing Lines

- Food & Drink Conveyor Belts

- Conveyors built for integration within other equipment

- Subcontract conveyor manufacturing

- Happy to work with resellers and OEMs

If you need modular conveyors for your business then please contact us by phone, email, or try out the live chat feature for a free no-obligation quotation.

Call:01482 363445

Email: sales@conveyorsystems.co.uk

Supporting our customers & their products

-

SUPPORT

Our excellent customer service team are available for ongoing customer support

-

DELIVERY

Conveyors delivered fully wired ready for work or installed by our team across the UK

-

WARRANTY

All products come with two year warranty & supplied UKCA / CE marked with associated manuals.

-

SERVICE

All products come with service packages to ensure optimal performance and ongoing reliability.

Contact Us

Contact us today to get your conveyor project started

Custom designed conveyor solutions

In-house design team

Helpful customer support team

01482 363445