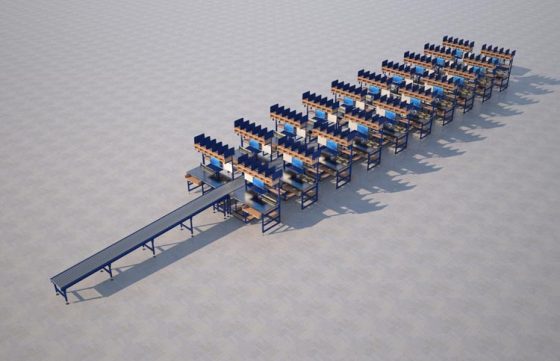

Packing Conveyor System

About the Company

In this instance the customer is battery manufacturer.

Products Supplied

We supplied lengths of belt conveyor and roller conveyor to create a packing conveyor line.

Services

The conveyor system was designed and installed by our team.

Get a FREE Conveyor Quote today

We are the leading UK manufacturer of stand alone conveyors for integration or full conveyor systems

Email sales@conveyorsystems.co.uk with your enquiries

Benefits of Integrating Conveyor Systems with Packing Tables in Warehouses

Integrating a conveyor system with packing tables in a warehouse offers numerous advantages because it significantly enhances efficiency, productivity, and safety. Key benefits:

Enhanced Efficiency and Speed

Streamlined Workflow:

- Continuous Flow: Conveyor systems facilitate a continuous, automated flow of goods to packing tables, reducing delays and bottlenecks.

- Increased Throughput: Automation of item movement to packing stations accelerates the packing process because it makes it faster and more efficient.

Reduced Manual Labor:

- Less Handling: Automating item transport minimizes manual handling and allows workers to focus on packing and also quality control.

- Faster Packing: Direct delivery of items to packing stations reduces retrieval time and boosts overall packing speed.

Improved Accuracy and Organization

Consistent Supply:

- Reliable Delivery: Conveyor systems ensure a consistent supply of items to packing tables because it reduces errors associated with manual transport.

- Organized Workflow: Items can be sorted and delivered to specific packing tables based on size, type and order, improving organization and accuracy.

Automated Sorting:

- Sorting Systems: Integration with sorting mechanisms automates the distribution of products to the appropriate packing tables because it enhances inventory management and order fulfillment accuracy.

Cost Savings

Labor Costs:

- Reduced Workforce: Automation reduces the need for a large workforce, lowering labor costs and allowing staff to be reallocated to more complex tasks.

Operational Costs:

- Lower Maintenance: Automated systems reduce wear and tear on material handling equipment, decreasing maintenance and also repair expenses.

Increased Safety and Ergonomics

Reduced Injuries:

- Less Lifting: Automating the transport of heavy or bulky items because it reduces the risk of injuries related to manual lifting and moving.

- Ergonomic Workstations: Ergonomically designed packing tables reduce strain on workers, improving comfort and productivity.

Controlled Environment:

- Safe Movement: Conveyor systems provide a controlled environment for product movement which also minimizes potential damage and workplace accidents.

Space Optimization

Efficient Layout:

- Customizable Design: Conveyor systems can be customized to fit the warehouse layout and make use of available space.

- Vertical Integration: Inclined and vertical conveyors make efficient use of vertical space because it further maximizes storage capacity.

Packing Table Integration:

- Compact Setup: Packing tables integrated with conveyors maximize workspace efficiency, reducing the footprint needed for packing operations.

Increased Productivity

Faster Order Fulfillment:

- Quick Access: Efficient delivery of items to packing tables speeds up the order fulfillment process.

- Minimized Delays: A seamless flow of items ensures that packing stations are consistently supplied, reducing downtime.

Enhanced Workflow Integration:

- Smooth Operations: Integrating conveyor systems with packing tables ensures a smooth transition between different stages of the packing process, from receiving to shipping.

Versatility and Scalability

Adaptable Solutions:

- Custom Configurations: Conveyor systems can be tailored to handle various products and packaging requirements, making them versatile for different industries.

Scalable Operations:

- Expandable Systems: The system can be scaled based on the volume of products handled because it allows for flexible and scalable operations.

Conclusion

Integrating conveyor systems with packing tables significantly enhances warehouse operations by improving efficiency, accuracy, safety, and productivity while reducing costs and optimizing space. Integration is a strategic investment for modern logistics and manufacturing facilities because it enables them to streamline their packing processes and boost overall operational performance.

For more information and tailored solutions, consult industry experts who can help design and implement the perfect conveyor system with packing tables for your specific needs.